Say Goodbye to Traditional Implants: The Future of Dentistry with 3D Printed Implants

Are you tired of the lengthy and often painful process of getting traditional dental implants? Well, get ready to say goodbye to that experience because the future of dentistry is here with 3D-printed implants! This groundbreaking technology allows for faster, more precise implant placement, resulting in a more comfortable and efficient patient process. In this blog post, we’ll explore how 3D printing is revolutionizing the world of dentistry and why it’s time to embrace this exciting new advancement. So sit back, relax, and get ready to learn about the future of tooth replacement with 3D-printed implants.

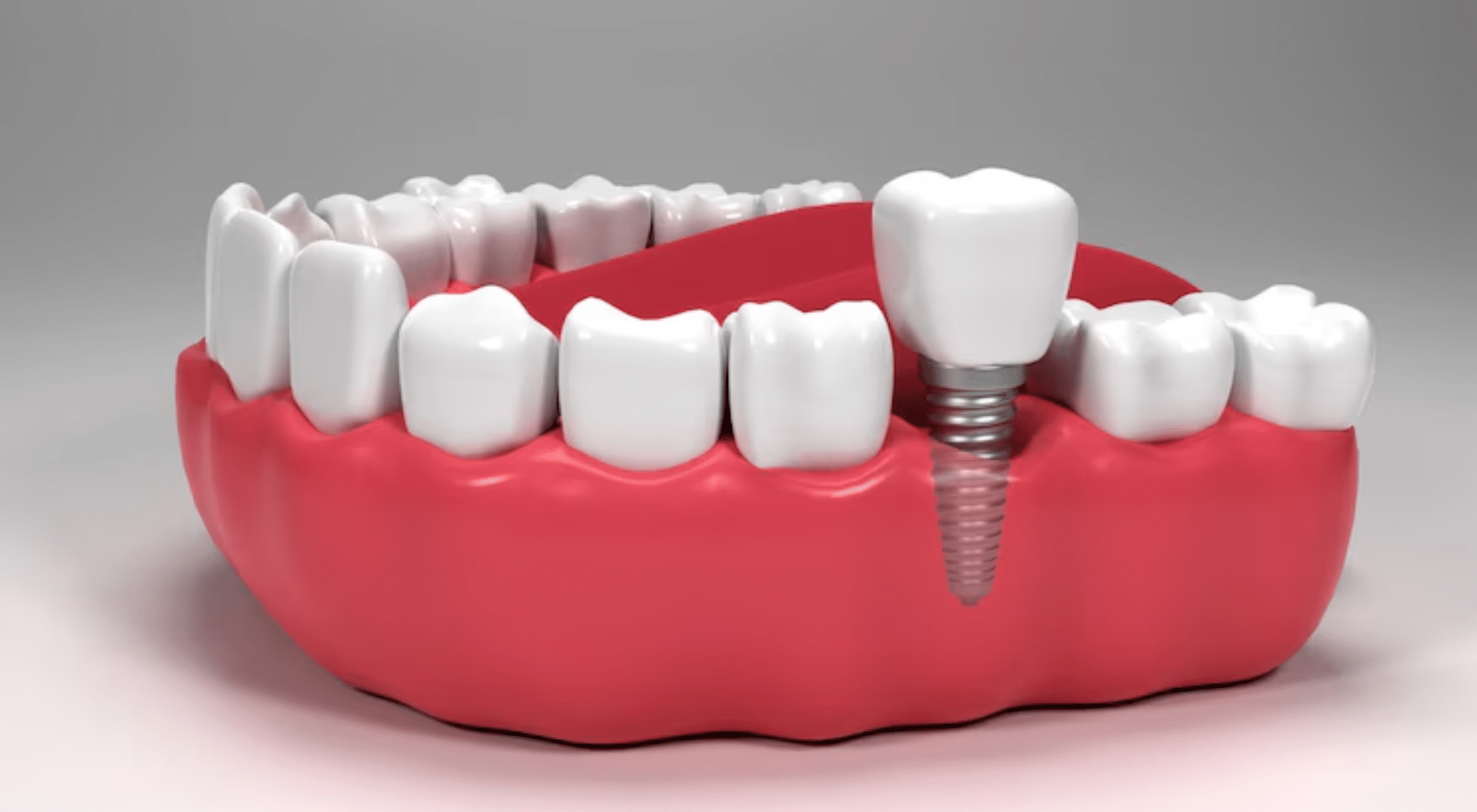

What are 3D Printed Implants?

Traditional implants are made from metal and other materials that can be difficult to replace or adjust. 3D Dental implants are made from various materials, including plastic, and can be printed in any desired shape or size. They are also customizable, allowing patients to choose the implant that best suits their needs.

3D-printed implants have several advantages over traditional implants. They are more easily replaced and adjusted and can be customized to fit the patient’s needs better. Additionally, 3D-printed implants may not require as much surgery to install them, which could reduce the amount of time patients spend recovering from their procedure.

How are 3D Printed Implants Made?

Traditional implants are made of metal and plastic and are often considered legacy technology. But what if dentists could print replacement implants using 3D printers? It is the future of Dentistry, according to some experts, as 3D-printed implants are more durable, customizable, and easier to replace.

3D printing is a process where objects are created by building them up from layers of material. Objects can be printed in any shape or size and are often used in the manufacturing industry to create parts quickly and cheaply. For example, dentists could use this same technology to create custom implants that perfectly fit each individual’s teeth.

It is already being done in Japan, where doctors have been printing dental crowns with lasers for years. As a result, custom-made crowns for each individual’s teeth can be replaced much more easily than traditional crowns, which can become loose over time.

3D printing process is also used to create other types of dental implants, such as bridges and dentures. Bridges are an implant that replaces two missing teeth with one artificial tooth. Dentures are also becoming increasingly popular as they offer a more natural look than traditional dental braces.

There are still some limitations to this technology, however. For example, 3D printers can only sometimes create very strong materials, so they may not be ideal for use in areas such as the jawbone or spine, where stress is often placed on teeth. But overall, 3D printing is

Benefits of 3D Printed Implants

Traditional dental implants have been around for many years, and while they have their benefits, they may soon be replaced by 3D-printed implants. These implants are made using a printing process that creates a solid object from a series of layers, which makes them more durable and less likely to fail. Here are some of the benefits of 3D-printed dental implants:

They’re More Durable

They are much more durable than traditional implants. It is because they’re made from a solid material, so there’s no chance of them breaking or becoming loose over time.

They’re Less Likely to Fail

They are also less likely to fail than traditional implants. It is because they’re made from a solid material, which means they cannot become damaged or corrupted over time.

They’re Cheaper to Replicate

They are also cheaper to replicate than traditional implant materials. They don’t require any additional tools or equipment to create them, and they can be produced in large quantities quickly and easily using modern technology.

What are the Current Limits of 3D Printed Implants?

Traditional dental implants are metal and rely on a surgical installation procedure. As a result, they are often associated with more pain, discomfort, and a longer recovery time.

However, this is changing with the advent of 3D-printed dental implants. These implants are made from plastic and can be fabricated using various methods, including 3D printing.

There are several benefits to using these over traditional ones. First, they are less invasive than traditional implants, requiring only local anesthetic rather than general anesthesia. It makes them more comfortable for patients and reduces the risk of complications.

They also have a shorter recovery time, meaning patients can return to work sooner after surgery than traditional implants. Finally, they are more affordable than traditional ones, making them an attractive option for dentists who want to offer their patients quality dentistry at an affordable price.

The Future of Dentistry with 3D Printed Implants

Traditional dental implants are made from various materials, including titanium and stainless steel. Over time, these materials can become brittle and prone to breaking. 3D printing may offer a viable alternative to traditional implants.

Source: Zahntechnique, Inc

3D printing technology is used to create objects from a digital file. This process allows for the rapid production of customized products. For example, dentists can use this technology to create custom implants that are stronger and more durable than traditional implants.